I like my cheap 18ga pneumatic brad nailer/stapler. I’ve had it for probably 6 years now, and even today it’s only $29.

The problem is that it’s easy, and great at pinning together joints with wet wood glue. I use it for all of the baseboards, etc. around the house. Nice things. Things that shouldn’t look like crap. But it makes things look like crap, because it does this.

All fine and dandy when you can put in some putty, sand, and touch up the paint. But that extra bit is a lot of work all said and done. The driver extends too far into the work.

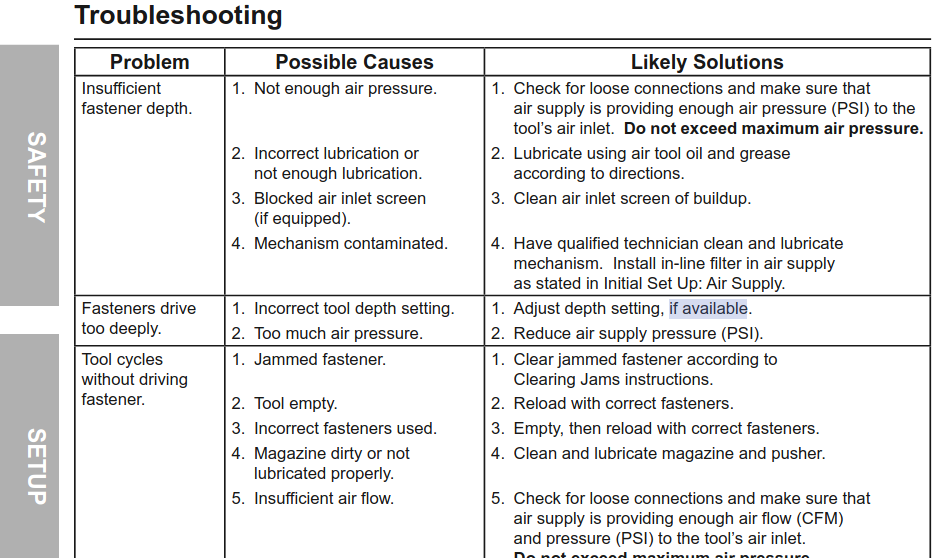

A lot of more expensive guns have a depth adjustment. This one… doesn’t. Or maybe it’s not sure if it does or doesn’t (it doesn’t). I think that’s actually worse. The person writing the documentation didn’t even take the time to understand the product. So I guess that’s a pretty good litmus test for what the rest of the product is like.

Some people have figured out how to modify the depth slightly with a zip tie.

I have a theory that we can just grind down the face of the driver to prevent this. Let’s see if we can make it work.

Remove two screws on the removable anti-jam faceplate or whatever they’re calling it. You can see the driver, but need to remove the entire feeder assembly off the bottom of the gun to get at it with a bench grinder.

This are only three cap head screws to remove. Minimal tools required - one 1/8" allen wrench, and one 5/32". The screw and rod for the safety interlock will try to shoot out. And the pin that the faceplate pivots on is only held in by the screw heads on either side. There is also a guide plate that holds the driver straight, which isn’t held in by anything.

Here it is fully disassembled.

Grind slowly. This should be heat treated, and if you ruin a temper your gun isn’t going to work well when it mushrooms. Or maybe it’s just pot metal, I wouldn’t be surprised either way. But we’ll take it easy just in case it’s a proper alloy.

And the big reveal! It doesn’t help all that much. It doesn’t consistently drive to the right depth. But it is much easier to control the divot with the supplied air pressure than it used to be. At some point I’ll do this again another sliver at a time. But for now it should work to put cabinet trim pieces back on without destroying the oak. And that’s good enough for me.